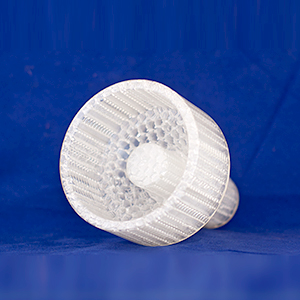

Stereolithography

We’ve been the leader in high capacity Stereolithography & SLS for more than 20 years

Stereolithography is the ideal choice for

- Form and Fit testing of new designs

- Functional parts for special projects

- Architectural models and one-offs

- Form and Fit testing of new designs

- Testing of new designs or reverse engineered parts

- Investment Casting patterns for QuickTurn cast metal parts

- Limited run production parts

Material choices include

- SL7520 – High-strength resin (durable, tough applications)

- SL7870 – Polycarbonate-like resin (rigid, temperature-resistant)

- SL5240 – Polypropylene-like resin (good for flexible and snap-fit parts)

- WaterShed 11120 – ABS-like properties, high clarity, good moisture resistance

- WaterClear 10120 – Ultra-clear resin, ideal for optics or fluid flow visualization

- Somos Raven 7620 – Black, stiff resin with good dimensional stability and surface finish

Additional SLA specs & info

Dimensional tolerances:

- +/- 0.005” or better for the first 3 to 4 Inches

Layer thickness:

- 0.002” to 0.006 depending on resolution

Build envelope:

- 20” x 20” x 24” (up to 10’ long by special order)

Delivery:

- Depending on size of part, but typical Turnaround for hand-held parts is 24 to 48 hours.

Wax patterns Replacement:

- Quickcast Patterns are used as wax patterns for investment casting of metals such as aluminum, steel, bronze, etc. (See Metal Castings).

Finishing types:

- 2A Finishing: Minimum surface sanding and a bead blast finish. Ideal for engineering check models and form/fit testing 3A Finishing: Each part is sanded and hand-finished, benched, and verified for dimensional accuracy and surface integrity. Ideal for marketing samples, trade show samples and ready for painting. Paint and Texture: Parts are painted and textured to exact color match and specified texture. A 3A finish is required prior to paint and texture.

Rapid prototyping stereolithography manufacturing gives engineers, designers, and inventors dimensionally accurate plastic parts they can hold, test, and show in a matter of days, instead of the weeks or months it used to take with conventional manufacturing.

Stereolithography (aka SLA or 3D layering or 3D printing) produces three-dimensional solid plastic objects directly from CAD data in a process that utilizes a ultra-violet laser and a large vat of photo-curable polymer liquid plastic. Working from a CAD file, stereolithography solidifies the polymer into precise patterns using a laser beam. Since they are created directly from 3D designs, SLA parts are extremely accurate, and are delivered with fast turnaround time without any compromise in accuracy or quality.