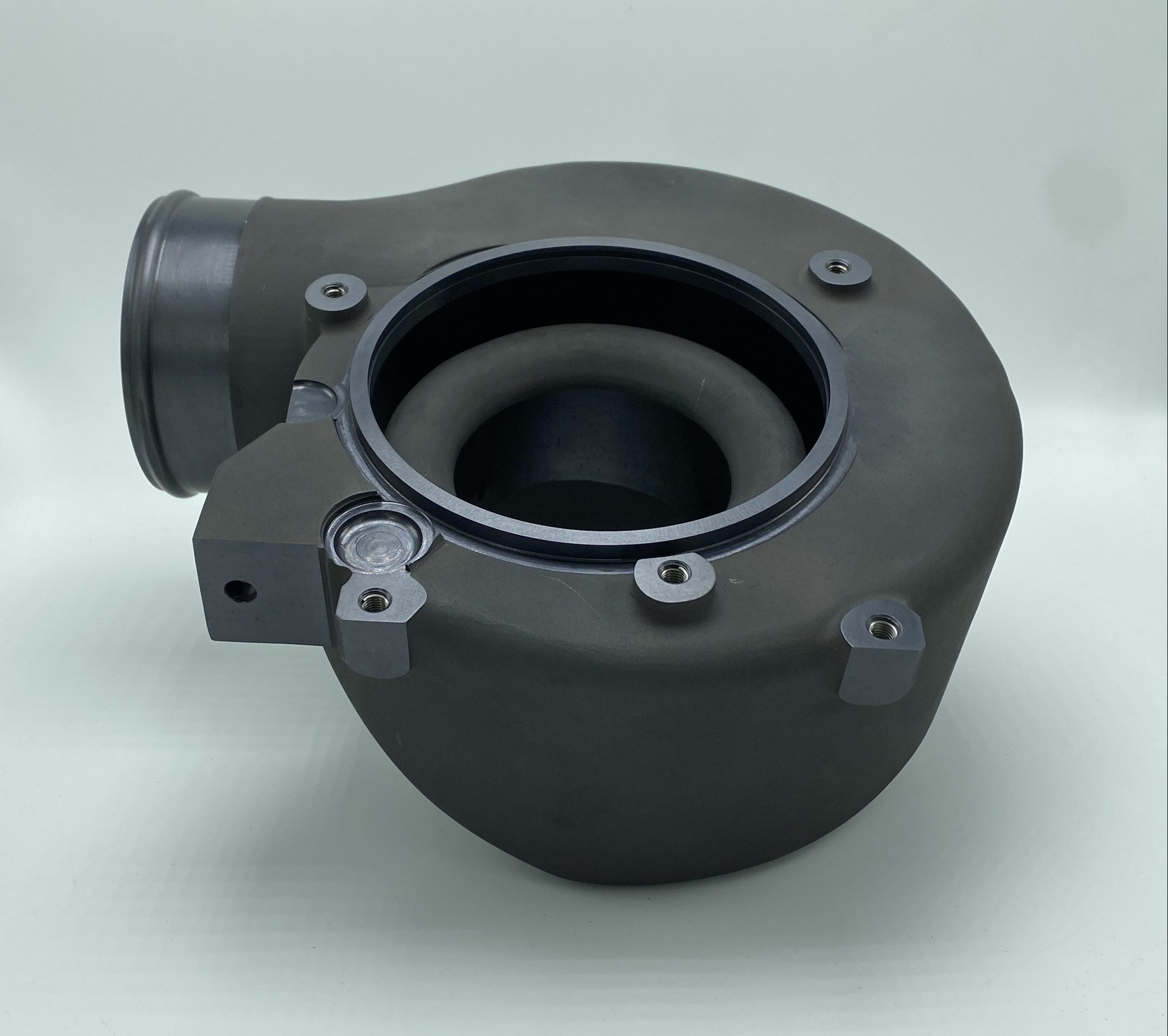

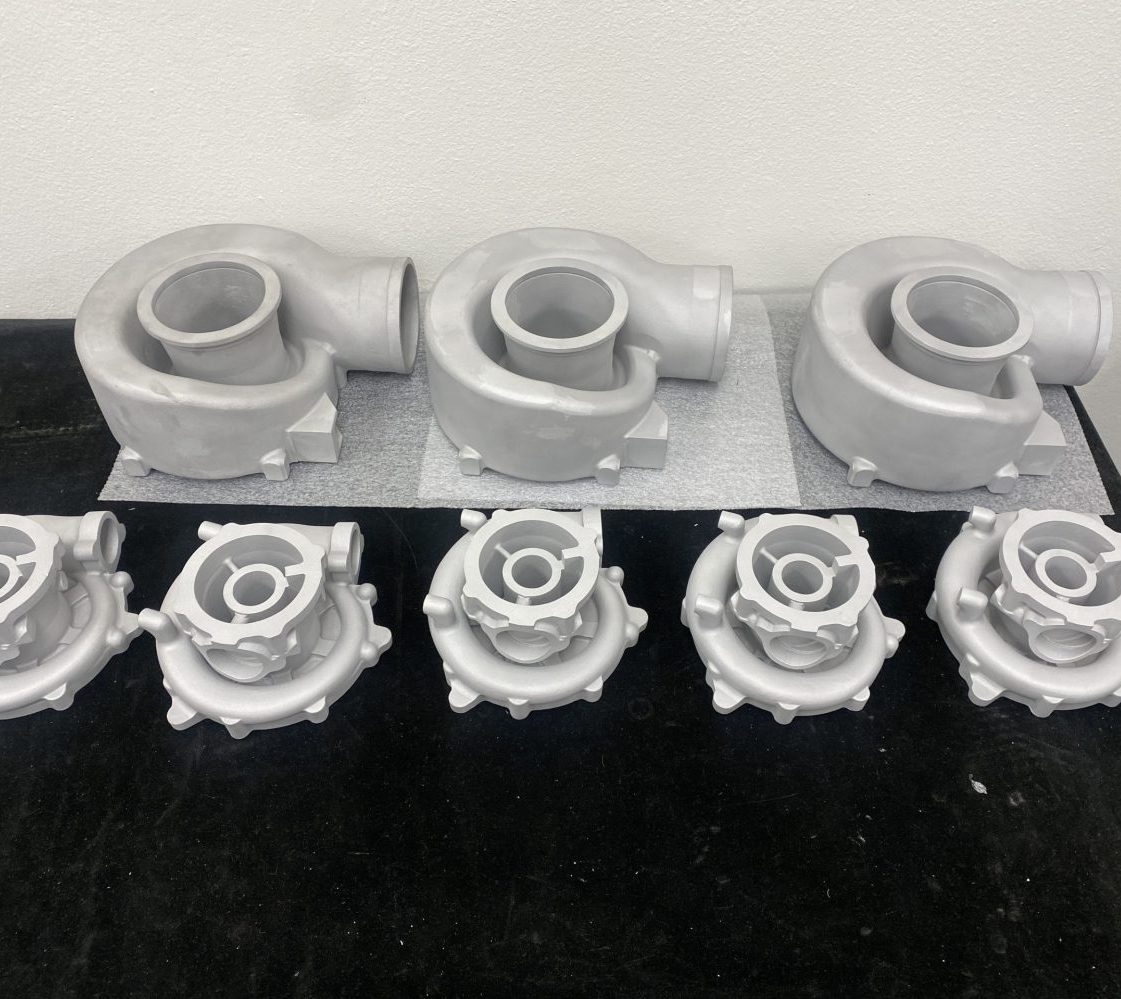

Metal Parts from Investment Casting

3D-CAM modernizes an Ancient Technique

3D-CAM has a cost-effective solution for any type of metal prototype you need

3D-CAM has a variety of ways to make the wax patterns for this process including:

- CNC-Machined wax tooling

- Epoxy-Aluminum tooling

- SLA Quickcast method to provide the plastic patterns for the investment casting

- SLS castform material to provide wax patterns for investment casting

- Investment Castings are ideal for:

- Quick, cost-effective metal prototypes and production parts

Material choices include:

Ferrous Alloys

- Gray Cast Iron

- Ductile Iron

- White Cast Iron

- Carbon Steel

- Stainless Steel

- Tool Steel

Non-Ferrous Alloys

- Aluminum Alloys: A356, 319, 535, etc.

- Copper Alloys: Bronze, Brass, Gunmetal

- Zinc Alloys: Zamak, ZA alloys

- Magnesium Alloys: AZ91, AM60

- Nickel Alloys: Inconel, Hastelloy, Monel

- Titanium Alloys: Ti-6Al-4V

Dimensional tolerances:

- +/- 0.020” to +/- .040”

- Post machining is necessary for

better tolerances

Turn-around:

- 1 to 3 Weeks after Quickcast or wax pattern availability

Finishing types:

- Bead blast or textured surfaces available 125 RPM

- Post machined accurate surfaces where necessary

- Polish

Investment casting (also called Lost Wax Casting), is one of the oldest metal-forming techniques. The castings allow the production of components with accuracy, repeatability, versatility and integrity in a variety of metals and high-performance alloys. The process uses a wax pattern invested in a ceramic shell made with multiple dips in a ceramic slurry. When the shell dries, it is baked causing the wax to melt away. Then metal is poured into the empty shell. When the metal is solidified and cooled, the shell is broken away.